In the field of manufacturing, every process has its limitations. Due to the inherent principles of 3D printing, the process often results in layer lines, leaving the initially printed parts less smooth and with limited color options, falling short of meeting consumers' diverse demands for product performance and aesthetics. As 3D printing technology transitions from the era of model-making to the 2.0 era of mass production for end-use products, the importance of enhancing surface performance has become increasingly evident.

To address this challenge, PollyFab has leveraged its comprehensive 3D printing technology capabilities to introduce the innovative PollyFab Microsurfacing Treatment System (PMTS). This groundbreaking process endows 3D printed products with vibrant color choices, refined finishes, and a soft touch, making them more competitive in the market.

PollyFab’s PMTS system plays a crucial role in enhancing the performance, aesthetics, and durability of end-use components. Whether in terms of color, surface texture, or resistance to wear, adhesion, and environmental factors, PMTS excels, ensuring that 3D printed parts maintain their luster and appeal over time.

By integrating PMTS technology into the 3D printing production process, combined with design flexibility and versatile color options, truly customized parts can be achieved. PMTS offers customers diverse solutions, considering factors such as geometric complexity, cost, process simplicity, production volume, and surface uniformity, bringing exceptional flexibility to 3D printing materials and unlocking new possibilities for high-end applications—ranging from functional prototypes to mass-produced end-use parts.

So, what are the unique features of PollyFab’s microsurfacing technology? What kind of effects can you expect once the final product is delivered? And what are the suitable application scenarios?

Let’s uncover the answers together!

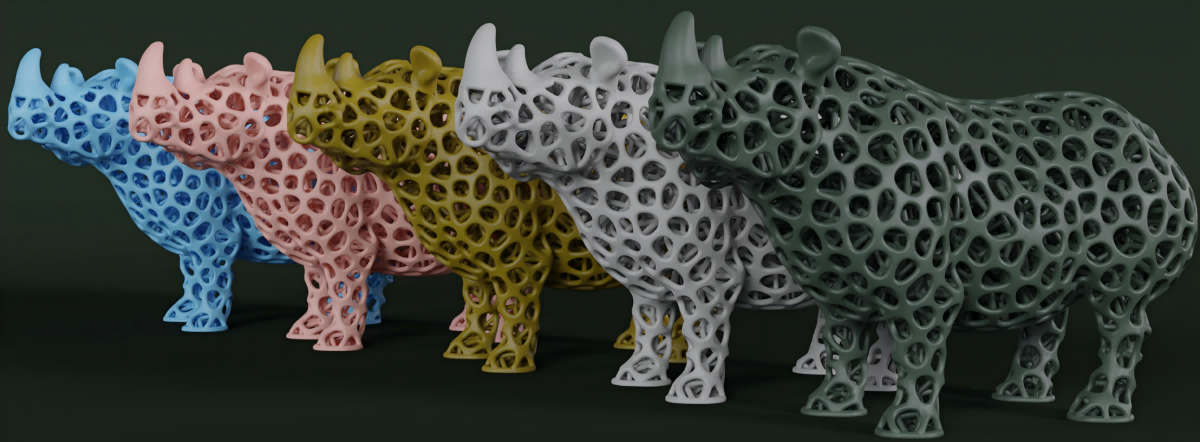

1. Customized Multifunctional Colors Creating a Broad Range of Colors and Surface Textures

Color is a critical factor in product development, directly influencing consumers’ perceptions, emotions, and the appeal of the product. PollyFab understands the importance of color in differentiating products and conveying functionality, which is why it developed a multifunctional color coating system, providing a wide range of gloss and color options.

PollyFab’s microsurfacing technology not only offers a rich palette with 12 standard colors but also supports the customization of PANTONE colors according to client needs. Its superior surface treatment significantly enhances the surface fineness and glossiness of resin products (especially elastomers), bringing out the ultimate beauty of the product.

Whether you seek a smooth, modern high-gloss finish or a subtle, refined matte surface, PollyFab’s microsurfacing technology can meet your needs, allowing you to customize the gloss characteristics of 3D printed parts.

Whether you seek a smooth, modern high-gloss finish or a subtle, refined matte surface, PollyFab’s microsurfacing technology can meet your needs, allowing you to customize the gloss characteristics of 3D printed parts.

Furthermore, this technology enhances the tactile experience of the product, making it more attractive and functional. Whether your goal is to create a smooth, velvet-like feel or a uniquely textured surface, PollyFab’s microsurfacing technology offers the flexibility to tailor the finish according to your specific requirements.

2. Gradient Colors for Superior Expression Outstanding Adhesion, Environmentally Friendly, and Safe

Whether working with elastomeric resins or high-toughness plastics, PollyFab’s microsurfacing technology provides exceptional aesthetics and durability. Even under the most demanding environmental conditions, the products maintain their excellent performance regardless of geometric shapes or strain.

As design requirements become increasingly diverse, PollyFab developed gradient color processing technology to address the customized needs of complex designs, adding more possibilities for the functionality and aesthetics of 3D printed end-use products.

As design requirements become increasingly diverse, PollyFab developed gradient color processing technology to address the customized needs of complex designs, adding more possibilities for the functionality and aesthetics of 3D printed end-use products.

Strong adhesion is a key feature of PollyFab’s microsurfacing technology. Tested rigorously, the treated surfaces exhibit high resistance to removal, offering long-lasting protection that is difficult to strip away.

Strong adhesion is a key feature of PollyFab’s microsurfacing technology. Tested rigorously, the treated surfaces exhibit high resistance to removal, offering long-lasting protection that is difficult to strip away.

Moreover, all processes applicable to these surface treatments meet industrial health and safety standards, and the materials used comply with relevant EU environmental standards, ensuring both safety and flexibility.

3. Enhanced Performance Ensuring Long-Lasting Appearance and Functionality

Preventing Discoloration/Yellowing: Discoloration is a common challenge for resin products. To combat this, PollyFab developed a new material capable of resisting various sources of discoloration, and rigorously tested it to verify its effectiveness.

Plastic parts typically yellow over time when exposed to sunlight. However, with microsurfacing treatment, the resistance to discoloration caused by UV rays or phenolic yellowing is significantly improved, ensuring stable color and effective preservation of the parts' appearance.

Durability/Robustness: To ensure the durability and longevity of surface treatments, PollyFab developed a new robust, wear-resistant process, excelling in areas such as abrasion resistance, adhesion, and anti-caking, allowing the product to withstand harsh environmental challenges while maintaining its appearance and integrity.

4. Diverse Application Scenarios Meeting the Needs of End-Use Consumer Products

Based on microsurfacing technology, PollyFab offers injection-molded quality 3D printed finished parts to customers, realizing the perfect fusion of functionality and aesthetics.

3D Printed Footwear: With PollyFab’s excellent elastomeric PollyFab materials and microsurfacing technology, designers’ creativity is fully supported. In the production of 3D printed integrated footwear, the mechanical properties and comfort of the materials are closely linked. PollyFab’s self-developed elastomer ELASTO series features excellent hardness, strength, and resilience, supporting the development of new products with rebound and shock absorption properties. This material also boasts outstanding elongation at break and wear resistance, providing 3D printed integrated footwear with greater abrasion resistance and longer lifespan.

With special microsurfacing technology, 3D printed footwear not only exhibits a beautiful matte gloss and comfortable touch but also offers excellent color and durability.

3D Printed Sports Equipment: A well-fitting bike saddle is crucial for every cyclist, as it significantly impacts both comfort and performance. Traditional saddle foam, facing challenges in design and performance, has seen 3D printing technology bring a new level of comfort, performance, and personalization to the product, enabling the mass production of uniquely customized saddles.

PollyFab’s microsurfacing technology provides bike saddles with a wear-resistant, glossy, and richly textured protective layer, offering a touch reminiscent of a master craftsman’s work. With multiple colors to choose from and the option to customize shades according to requirements, the technology ensures excellent adhesion and elasticity, making it particularly suitable for lattice-structured bike saddles.

3D Printed Cultural Products: In achieving the large-scale production of 3D printed end-use parts, rapid and high-quality surface treatment for different materials has become critical.

Through flexible microsurfacing technology, PollyFab customizes exclusive colors for cultural products. The National Museum, by introducing high-performance materials, has achieved complex geometric structures, elevating the texture and expressiveness of 3D printed cultural products beyond traditional methods.

Through flexible microsurfacing technology, PollyFab customizes exclusive colors for cultural products. The National Museum, by introducing high-performance materials, has achieved complex geometric structures, elevating the texture and expressiveness of 3D printed cultural products beyond traditional methods.

As the trend of direct production of 3D printed end-use parts continues to grow, PollyFab's microsurfacing technology will bring exceptional performance, aesthetics, and durability to these products. In the future, we look forward to using diverse surface treatment technologies to help you unleash your extraordinary creativity, achieving a perfect blend of aesthetics, durability, and functionality, and jointly shaping the future of 3D printed end-use manufacturing.