Introduction

In the competitive world of sports footwear, innovation is key. Athletes and sports enthusiasts want more than just good-looking shoes—they need footwear that improves their performance, offering the right mix of comfort, support, and durability. As the industry moves towards advanced technologies, traditional manufacturing methods are finding it hard to keep up. PollyFab, with its years of expertise, has developed a new lattice structure technology that not only solves the issues of older techniques but also opens up new possibilities in sports shoe design.

Essential Elements of High-Quality Sports Shoe Design

A great sports shoe is much more than just something you wear on your feet—it’s an important tool for athletes. It connects their feet to the ground and helps them perform at their best. To design such a shoe, you need to carefully balance comfort, support, breathability, and durability. The shoe must stay stable in different conditions while being flexible enough to handle various sports activities. Every part of the shoe must be designed with care to ensure it not only meets but enhances the athlete’s performance.

The Challenges of Traditional Manufacturing Methods

For many years, sports shoes have been made using traditional methods. Even though these methods have improved, they still don’t fully meet today’s needs. Materials like EVA foam are light and cushioned but lose their bounce over time, affecting comfort and durability. Designers often find it hard to balance making shoes lighter while keeping them strong. Also, traditional shoe construction is complicated, requiring many steps and parts, which raises costs and quality risks.

Introducing PollyFab's Lattice Structure: Redefining Sports Shoe Design

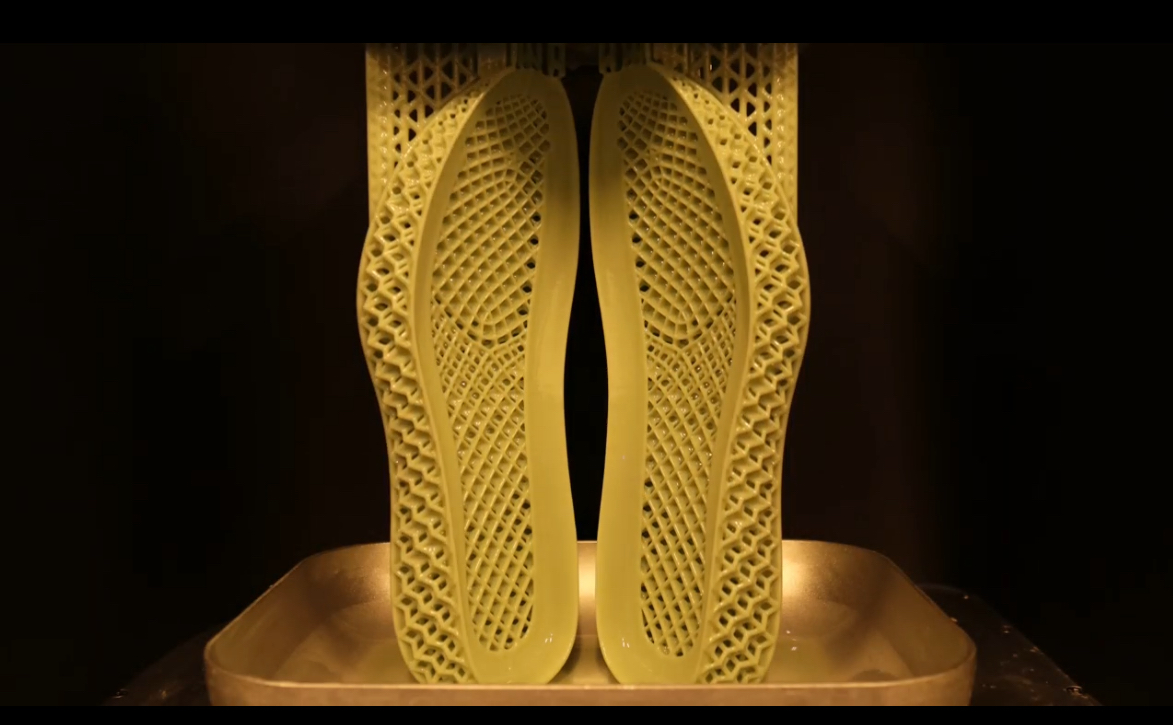

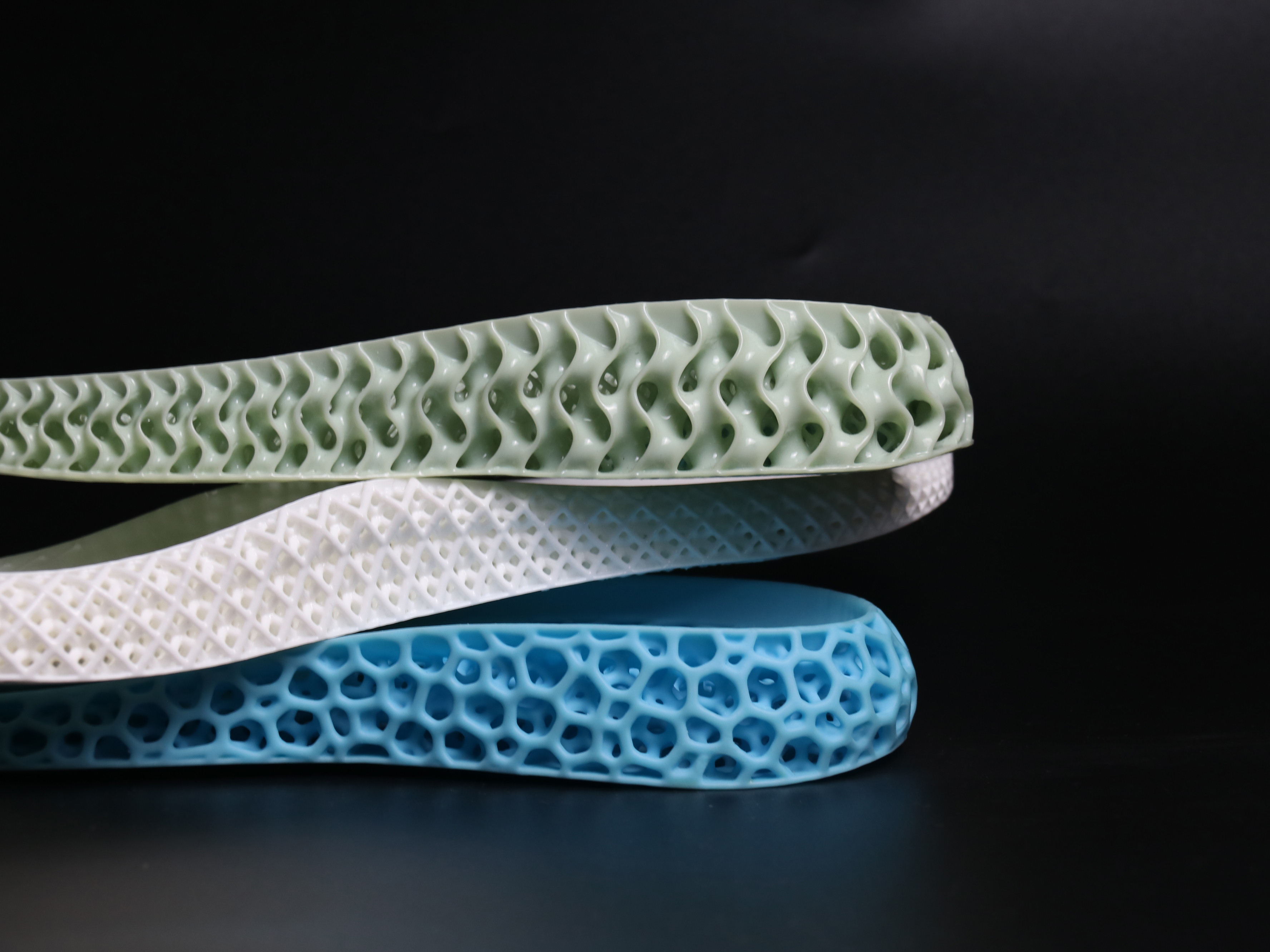

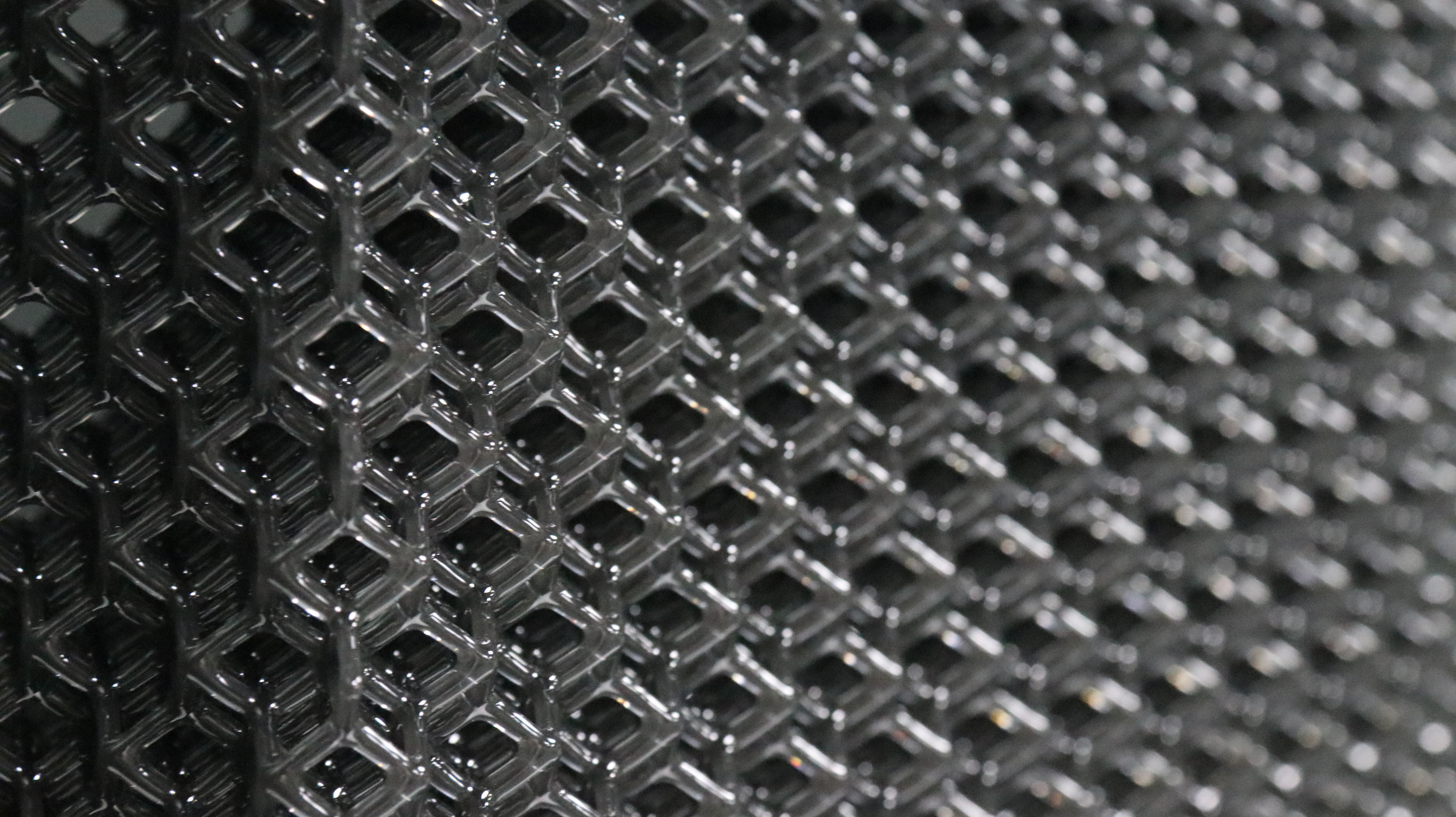

To tackle these challenges, PollyFab introduced its innovative lattice structure technology. Using advanced 3D printing techniques, this technology allows for the creation of detailed geometric patterns within the shoe. This optimizes the use of materials and gives the shoe outstanding qualities like being very lightweight, highly breathable, easy to clean, and simpler to make. One major advantage of PollyFab’s lattice structure technology is that it can create different structures within a single part of the shoe. This means designers can customize various parts of the shoe to meet specific needs by changing the density, shape, and arrangement of the lattice—all in one piece. For example, the front of the shoe can have a softer lattice for better cushioning, while the heel can be more rigid for extra support. This versatility not only makes the design and manufacturing process simpler but also reduces complexity and potential quality issues, resulting in high-performance, unique products.

- Breathability: The open-cell design of the lattice structure improves airflow, helping to keep the shoe cool and comfortable.

- Ease of Cleaning: Unlike traditional foam materials that can soak up water and are hard to clean, PollyFab’s lattice structures are water-resistant, easy to clean, and dry quickly, making the shoe more practical and long-lasting.

Application of Lattice Structures in Sports Shoes

PollyFab’s lattice structure technology shows its benefits in different parts of sports shoes:

- Midsole: The midsole is the heart of the shoe’s cushioning system, responsible for absorbing impact and providing comfort during activities like running and jumping. PollyFab’s lattice structures allow designers to create midsoles that have precise control over cushioning. By adjusting the lattice pattern, density, and structure, specific zones within the midsole can be made softer or firmer depending on the needs of the athlete. For instance, a runner might need softer cushioning at the front for better shock absorption and a firmer structure at the heel for stability during heel strikes. This customization ensures that the midsole not only provides optimal comfort but also enhances the performance of the athlete by offering support where it’s most needed. Additionally, because the lattice structure can be integrated into a single piece, it eliminates the need for multiple layers or glued components, making the midsole lighter and more durable.

Insole: The insole is where comfort meets customization. It directly affects how the shoe feels against the foot and plays a crucial role in providing support and reducing fatigue during prolonged use. With PollyFab’s lattice technology, the insole can be tailored to match the unique pressure points and foot shape of the wearer. The lattice structure can be designed to offer extra cushioning in areas where the foot bears the most weight, such as the ball of the foot and the heel, while providing firmer support in the arch to prevent overpronation or underpronation. This personalized approach not only enhances comfort but also improves foot alignment, reducing the risk of injuries. Moreover, the open-cell nature of the lattice allows for better air circulation, keeping the foot cool and reducing moisture build-up, which can cause blisters or discomfort.

Pollyab’s lattice structure has changed the game in sports shoe design, solving many of the problems with traditional manufacturing methods and giving designers more freedom. If you’re interested in learning how lattice structures can bring new ideas to your product designs, contact us at contact@pollyfab.com. Let’s explore the endless possibilities in sports shoe design together!

Pollyab’s lattice structure has changed the game in sports shoe design, solving many of the problems with traditional manufacturing methods and giving designers more freedom. If you’re interested in learning how lattice structures can bring new ideas to your product designs, contact us at contact@pollyfab.com. Let’s explore the endless possibilities in sports shoe design together!